Bartec Auto ID have been providing plant TPMS test systems and processes since before 1999. Our provision can support the supply of a single hand tool to a full turn-key vehicle production line TPMS test process from start to the end of a project. Our experienced Plant team are able to support you in:

- Initial assessment & site survey

- Advice on processes and best practise & equipment selection

- Key areas of concern and containment and build, installation & commission

- Training, maintenance and long term running / support and system preservation

Many customers worldwide are already benefitting from the high technology and robust TPMS reading products produced by Bartec Auto ID Limited.

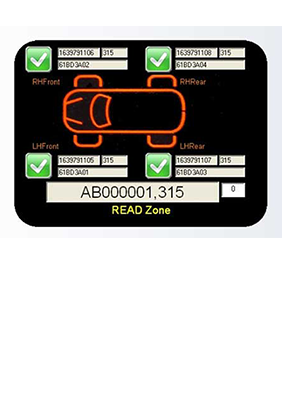

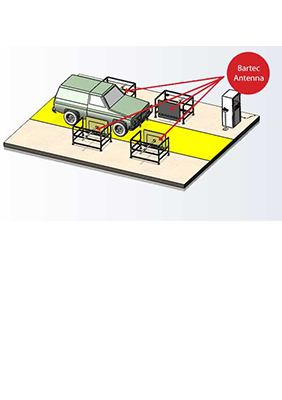

Testing in the tyre and wheel assembly area gives an additional level of quality that the assembled part is good and also provides error proof checking to the customer to ensure the right part is first time fitted.

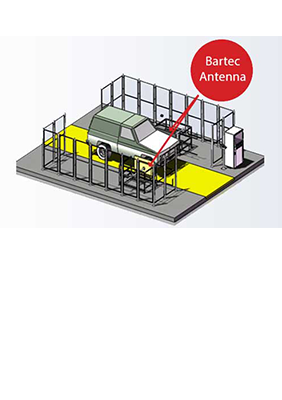

Testing the TPMS wheels in the vehicle assembly area gives the most secure process that the wheel read is actually the one fitted to the vehicle.

The best technology from the world leader in the TPMS field, look no further. Bartec Auto ID Limited offers the highest available antenna technology that is available on the market today.

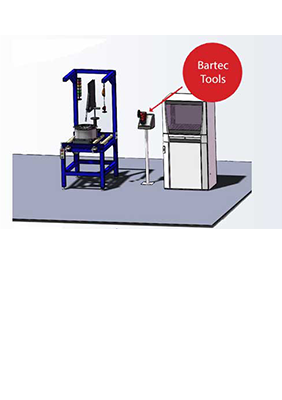

Using hand tools can offer an initial advantage when volumes are low. These can then be used for repair and rework when volumes increase. At that time automated antennas can be used to support the production process instead.